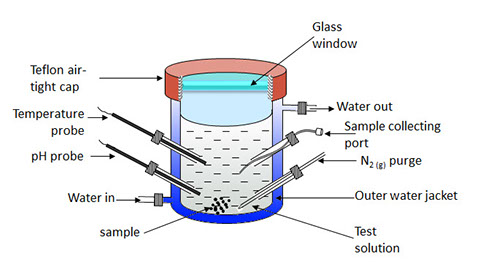

Custom-built Glass Reactors for Dissolution Studies

Dissolution measurements are conduced as batch reactor studies in custom-built glass reactors. The glass reaction vessel has a capacity of 100 mL and is stirred using a magnetic stir bar. The vessel has a quartz window with an area of 15 cm2 mounted on top that permitted deoxygenated experiments and is removable to allow for dissolution reactions to proceed under atmospheric conditions. For experiments that requires anaerobic conditions, suspensions are purged with N2 for ∼15 min at flow rate of ~120 mL/min, prior to dissolution. And during the experiment, the head-space of the reaction vessel is purged to maintain positive N2 pressure. The temperature is kept constant, usually at room temperature, through the use of a water jacket integrated to the reaction vessel and monitored throughout the experiment. The pH of the reaction medium is constantly monitored with a glass electrode standardized with pH buffer solutions. Experiments are performed at constant pH and are adjusted with HCl as necessary. Over time, samples are periodically removed from the reactor using a disposable syringe that is connected to 12 cm of Teflon tubing. Aliquots (1 mL) are collected after passing through a 0.2 μm PTFE filter and save for analysis. In photo-induced dissolution experiments, a solar simulator with a 150 W xenon solar simulator (~ 1 sun, Newport) is placed above the quarts glass window.

ADMINISTRATIVE ASSISTANT

GAYAN R. RUBASINGHEGE

Associate Professor of Chemistry

New Mexico Institute of Mining and Technology

Department of Chemistry

801 Leroy Place

Socorro, NM 87801

Bethany Jessen

New Mexico Institute of Mining and Technology

Department of Chemistry

801 Leroy Place

Socorro, NM 87801

Phone: 575-835-5129

Fax: 575-835-5215

Phone: 575-835-5263

Fax: 575-835-5364

Copyright © 2018 The Environmental Chemistry Research Research Group. All rights reserved.